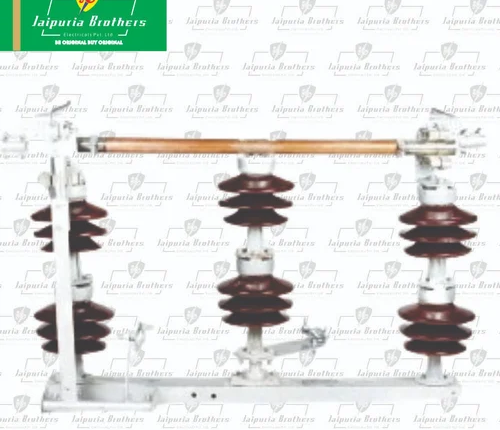

The isolators / disconnectors are mechanically operated safety device incorporated for electrical isolation of system. Open position provides safe and desired isolation. Hence, they are widely used in high voltage installations, transmission and distribution layouts for isolation of part or complete electrical system for carrying out maintenance, repairs and similar activities where the system has to be isolated from incoming supply.

Types

| Particulars | For Mains | For Earth |

| Rated Voltage | 11 kV, 22 kV, 33 kV, 66 kV, 110 kV, 132 kV, 220 kV | 11 kV, 22 kV, 33 kV, 66 kV, 110 kV, 132 kV, 220 kV |

| Highest System Voltage | 12 kV, 24 kV, 36 kV, 72.5 kV, 123 kV, 145 kV, 245 kV | 12 kV, 24 kV, 36 kV, 72.5 kV, 123 kV, 145 kV, 245 kV |

| Current Rating | 400A, 630A, 800A, 1250A, 1600A, 2000A, 2500A | Banging Type |

| Type | 1) Banging Type 2) Turn & Twist Type 3) Horizontal Double Break (HDB) 4) Vertical Single Break (VSB) 5) Horizontal Single Break (HSB) 6) HDB with UNDERHUNG | For : 1) 11 kV – 13.1 kA for 3 seconds 2) 33 kV – 26.5 kA for 3 seconds 3) 66 kV – 40 kA for 3 seconds 4) 132 kV – 40 kA for 3 seconds 5) 220 kV – 40 kA for 3 seconds 6)400 kV – 40 KA for 3 seconds |

| STC Value | For : 1) 11 kV – 13.1 kA for 3 seconds 2) 33 kV – 31.5 kA for 3 seconds 3) 66 kV – 40 kA for 3 seconds 4) 132 kV – 40 kA for 3 seconds 5) 220 kV – 40 kA for 3 seconds 6)400 kV – 40 KA for 3 seconds | |

| Operating Mechanism | Motorized Operating, Manual Reduction Gear Operating , Manual Operating (as per customer requirements) | |

| Support Structure | Pipe type structure & Lattice / channel type structure (as per customer requirements) | |

| Insulator Creepage | Normal Creepage (25 mm /kV) OR Higher Creepage (31 mm/kV) (as per customer requirements) |

Testing Approval

Following tests carried out at Electrical Research & Development Association, Vadodara and Central Power Research Institude Bhopal cleared in accordance with IS-9921 (part I to V) / IEC-60129 / IEC -62271 (102)

- Short Time Current test for mains & earth switch.

- Temperature Rise test.

- Lightening Impulse Voltage Withstand test.

- Dry Power Frequency Voltage Withstand test.

- Wet Power Frequency Voltage Withstand test.

- Mechanical Endurance test.

- RIV Corona test.

- Seismic test.

- All type of AL Terminal Connectors are type Tested.

Features

- Designed using the latest STAAD software to ensure technical precision and maintenance-free operation.

- Built with sturdy construction for long-lasting performance.

- Consistent contact pressure and low contact resistance are reliably maintained over extended periods.

- Adjustable horn bars are provided to ensure smooth engagement and disengagement of the moving blade with the fixed contact.

- Engineered to withstand high static loads without deflection.

- Each phase is equipped with an individual stopper to ensure precise alignment of the moving blade with the fixed contact.

- A fully enclosed canopy protects the operating mechanism, effectively sealing it from environmental contaminants such as rain, snow, dust, and other foreign materials that could impair isolator performance.

- Both “banging” and “turn & twist” operations are smooth and reliable.

- The copper pipe used in the turn & twist mechanism is fitted with two self-lubricating brass bushes to ensure smooth and frictionless movement.

Operating Mechanism

Both the main isolators and earth switches are equipped with a single operating mechanism, designed to operate independently. The isolators feature either a manual or motorized operating mechanism, mounted beneath the base, with an operating handle or control box positioned at an accessible height for ease of use. A common operating system is employed, utilizing a tandem pipe arrangement for all three phases of the main isolator, and a similar setup for the earth switch. Each phase assembly can be adjusted along the tandem pipe, allowing precise alignment to ensure proper contact as required.

Manual operating mechanism :

- Manual operating mechanism is provided with operating handle.

- As a safety measure, the operating handle comes with insulation. We use heat shrinkable sleeves for Isolators and PVC sleeves for AB Switches, as insulating material.

- Operating boxes conforming to IP-55 / IP-67 grade are provided and fabricated out of MS / AL / SS sheet (powder coated / painted).

- Interlocking arrangement.

- Safety locks for both mains and earth in open and close position alternately.

Motorized operating mechanism :

- Motor and reduction worm gear are coupled to increase the output torque.

- Over load protection provided.

- Remote control can be provided – optional.

- Certified auxiliary switches are incorporated.

- Operating boxes conforming to IP-55 / IP-67 grade are provided and fabricated out of MS / AL / SS sheet (powder coated / painted).

- Interlocking arrangement.

- Safety locks for both mains and earth in open and close position alternately.

Installation

The major assemblies and sub-assemblies of isolators and earth switches are manufactured and assembled in-house to ensure quality control and precision. All three individual phases are accurately aligned and mounted on their respective bases. A dedicated installation guide is provided to facilitate quick, safe, and hassle-free installation, eliminating the need for specialized tools.

Main installation to be done on site

- Erection of structure.

- Mounting of individual phase on structure.

- Mounting earth switch and operating mechanism on structure.

- Connection for supply through braided copper flexible and terminal connectors.

Maintenance

- Annual maintenance is recommended to ensure reliable and trouble-free operation.

- The isolator design is inherently maintenance-free; however, for long-term operational safety, periodic inspections are recommended.

- Inspections can be carried out either visually or using appropriate equipment, depending on the criticality of the installation, available diagnostic tools, future operational requirements, and whether the system is in an operational or non-operational state.

- Lubrication should be carried out during idle periods using the grease or oil cups provided for components involved in rotary motion.

Services

- We also offer installation, erection, retrofitting, and maintenance services as per customer requirements.

Hot Dip Galvanizing of Support structures for substations, gantry, isolators & other equipments

We operate a state-of-the-art in-house Hot Dip Galvanizing facility, making us one of the few isolator manufacturers in India with this capability.

- Galvanizing Kettle Size: 6.50 meters (L) × 0.80 meters (W) × 1.40 meters (D)

- Monthly Capacity: 900–1000 metric tons

This in-house setup ensures superior corrosion protection, consistent quality, and faster project turnaround.