Manufacturing facilities:

- Infrastructure : Around 1,80,000 Sq. Feet Area.

- Machining :Turning, Drilling, Tapping, Grinding, Polishing, Boring, Facing, Internal Threading, Thread rolling etc.

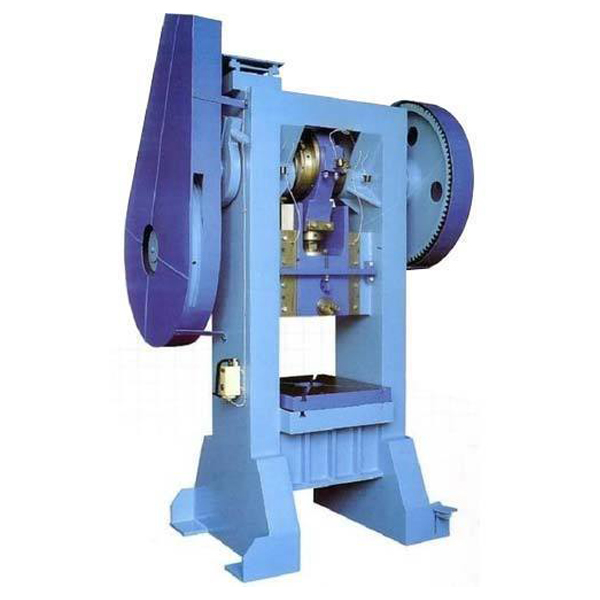

- Press work :V-bending, Punching, Angular bending, Forming, etc.

- Shearing & Bending : Shearing and bending up to 2500 x 8 mm

- Die shop : In house tool room facility.

- Welding : MIG welding, AL welding, Automated rotary welding, Arc welding etc.

- Assembly : Complete automated assembly line (Pneumatic).

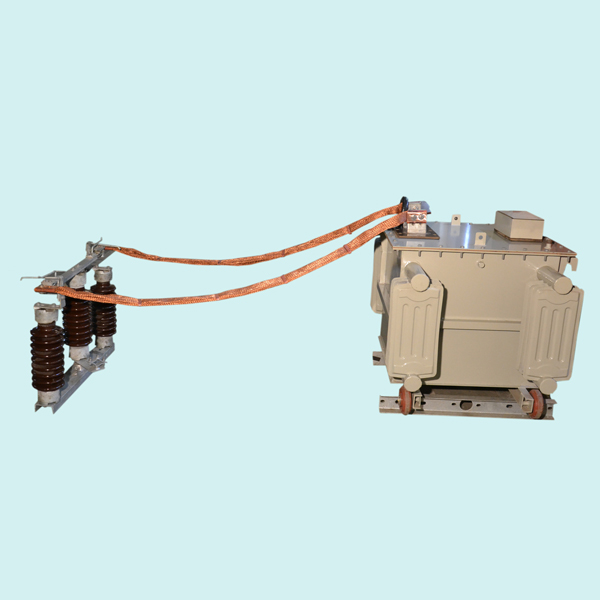

Machine Photos :

List of In-house testing facilities

- HV tester 5 kV, 100 kV, 300 kV

- Temperature Rise test upto 3000 Amp

- Contact resistance measurement scope CRM-100

- Plating thickness tester for Silver and Tin plating

- Coating thickness tester for Hot Dip Galvanizing

- Motwane’s Megger tester (insulation)

- Conductivity tester for non-ferrous materials

- Universal Testing Machine (UTM)

- Hardness tester

- Mechanical Endurance test set up

- Load tester for springs

- Mechanical Endurance test setup for springs

- Continuity Test for motorized box

- Chemical test by Spectro meter

- Magnetic particle inspection tester

- Horizontal tensile testing machine